-

Content Count

6,454 -

Joined

-

Last visited

-

Days Won

240

Posts posted by RPM

-

-

Shoulda bought a good cigar :)

Bob

-

Check with Powershift on his build in the garage section. I do know that new are quite pricey, but oh so cool!

Bob

-

Thanks for the kind words guys. It was rather easy to fab. I had seen the mounting style in racing applications before and thought it would look and work better than the stock crushed tube end. I'm no engineer, but I think a tube with two bends is stronger than a tube with four bends. I bought some thick fender style washers that had a 3/8" hole which I put a 1/2" taper into the match the mounting bolt. I then welded the washer to the angle cut short verticle tube. I bolted those two pieces to the frame rails and fit the cross piece. I tracked it into position, and finish welded it off the car. I later welded verticle brackets to the top of the cross tube which bolt to the lower control arm mounting bolt.

Bob

-

Looks like a cool and not so difficult mod. So I take it that the vehicle fender/door gap is not affected?

Bob

-

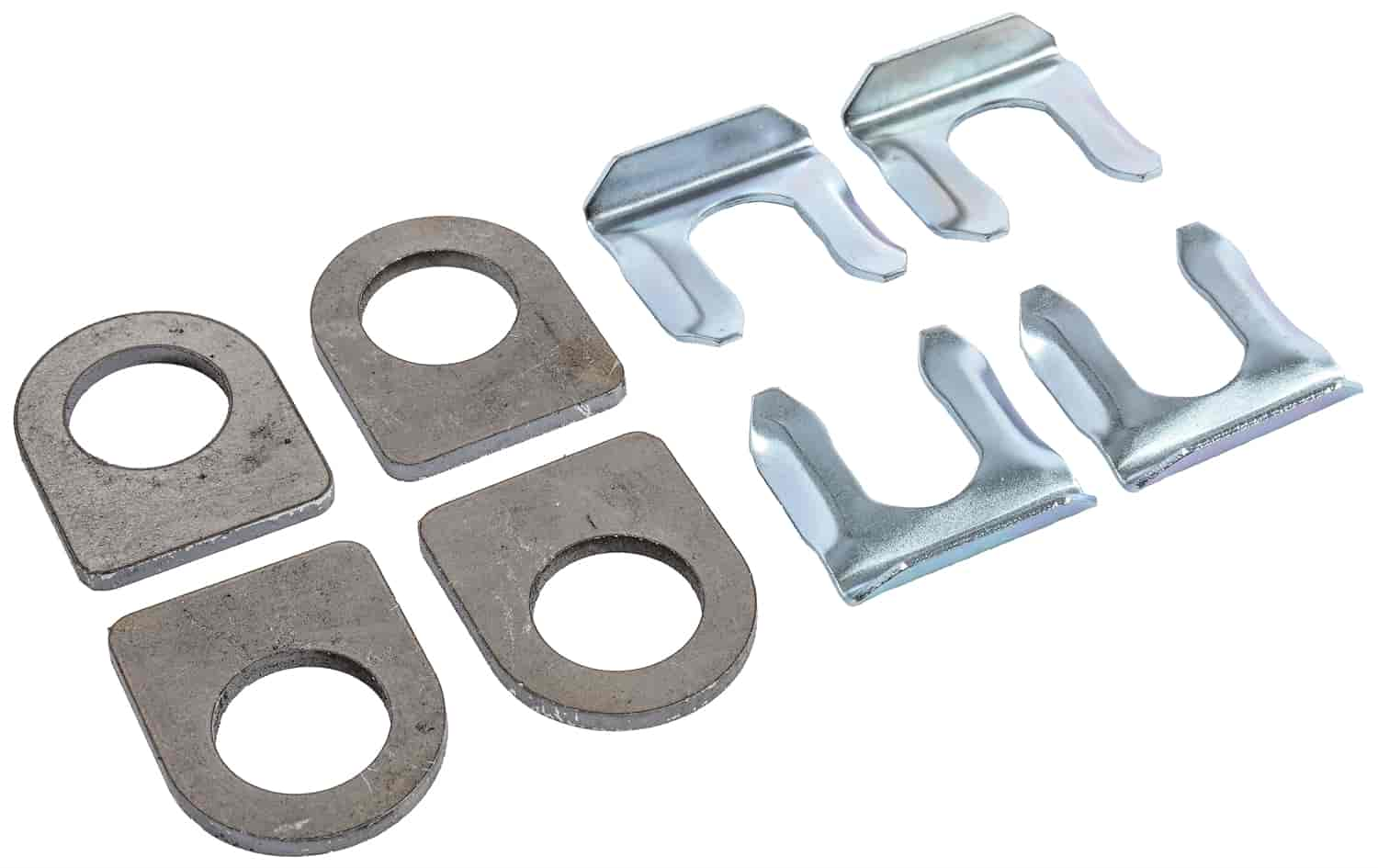

I think I went down this path for my SSBC rear disc conversion. I found for the time it took me to make the weld-on line tabs, I could buy them and the clips cheaper.

I found it quite easy to hand file the hex shape in the round hole. Only took about 10 minutes each. For the future, where did you find the hex hole brackets?

Bob

-

I did not find the clip parts, which leads me to believe they were not put in.Thanks.

Does the wrist pin at piston bottom drop below the cylinder skirt with those

pistons? If they don't they're captive and you will find them between the piston and cylinder wall. Otherwise they will drop into the pan. I don't see any damage to the wall other than the pin damage. Me thinks they were left out. Kinda odd both clips would fail on the same piston. Are these spiral locks?

Bob

-

Looks like sleeves are in my future.Did the wrist pin cause that damage?

Bob

-

Where the hell have I been? That's the first I've seen our heard that you have a GT! Very nice indeed.

Bob

-

That gusset is part of a Shelby mod to the crossmember. It also includes a hole for the lower control arm mounting bolt.

I believe the stock crossmember is a poor design at best. In order to lower my motor I built a cross member with only two bends, is made from 1-1/2" chromo, and actually looks like it belongs.

If I could post a pic I would, link to my photo bucket.

Bob

-

For calipers, get high temp paint made for them at any parts store. My understanding is that por15 needs to be painted for UV protection.

Bob

-

I've never replaced my floors, rockers or any other structural parts. I would place them under the front and rear torque boxes, and probably also support the front and rear rails. Before others reply, I would check the project progress forum, several guys have done it.

Bob

-

16? And bought your first classic Mustang for $2,500? Wow! Congrats and welcome to the forum. If you're anything like the rest of is here, you'll change your plans before the car is done. Fwiw, with that many cubes, and well over 500hp, saving weight with plastic windows is probably not needed. If you're going to shave weight, take it off the front end.

BTW, this thread is worthless without pictures! No pictures =no car. Post em up.

Bob

-

We always go with the 351 w and stroke them to a 427.How do you get 427ci out of a stock 351w? Who makes the crank? Back when I stroked my 351w the max a/m crank was 393. My brother machined a Mopar crank to get 421ci. As others have said there is a lot of good stuff now from which to choose.

Edit: I lied about the Mopar crank. He offset ground a 400 crank and used Mopar rods. Well, didn't really lie, just forgot and mixed up the facts.

Bob

-

Nice work on screwing up one of the most classic fords by putting a gm engine in it.Well, at least the next guy who owns the car car put a correct motor back in it.

Bob

-

Re your new garage/shop, garagejournal.com is a great place to get ideas. Many affordable cool places along with mega buck dream shops. My advice would be run run more electrical than you think you need, and run flexible conduit from the main or sub panel for future circuits. Future stubs are actually code in my area. Nice vehicles, including the Airstream. Good luck.

Bob

-

Hey Kevin, what part of France do you live? My maternal grandmother was born in Paris, and grandfather in Gap. Lots of Basque folks here in Bakersfield. Any exterior pics of your Stang?

Bob

-

Where are you located? You can add your location to you profile. Go to

car-parts.com

enter your zip code and the parts of the country you want to search. Easy least. I bought mine locally at a place that does restos and has parts cars, Bills Collectables. Good luck.

Bob

-

Any progress is good. Dang, you be a young buck.

Bob

-

Damn, kudos to your wife! Does she have a single twin sister??? Mine is still in the home shop under Fred Flintstone power.

Bob

-

Hi Bob, British Columbia Canada. It's a rigidly enforced requirement here.Regards,

Tony

Oh! I sometimes forget folks live somewhere other than California ;)

Bob

-

Think I spent all of $25 for a used hub. Still a lot of them out there.

Bob

-

If you use a Monte Carlo bar, make sure it is a straight one and preferably mounts to the shock towers and not the fender aprons.Jim

Super ditto!

-

Bolt em in!

Bob

-

I contemplated using them on my 69. Because my front end is pristine, using a Monte Carlo bar and export brace, subframe connectors, convertible inner rockers and one piece seat riser, it would be plenty stiff for street use. Your application should depend on car condition and use.

Bob

Happy Thanksgiving

in The Garage

Posted · Report reply

Thanks Jim, hope you had a good long weekend.

Bob