lseann

-

Content Count

16 -

Joined

-

Last visited

Posts posted by lseann

-

-

When I did my coupe headliner, had it all installed and looking good but forgot to cut for the dome light. Hooked up the batt to take it for a spin and the bulb melted away the headliner in that spot, ha. Could have been a real disaster but luckily it just made it easier to trim for the light location.

-

I bought a set of those universal belts a few years ago and they work good. If you see a set you like maybe just find out the approx measurements you have to work with and ask the seller if the belts will work for you. Otherwise try to find a universal seat belt manufacturer website and maybe they could offer more info about what might work in your car.

-

Search on ebay for "universal 3 point seatbelts". Lots of em for decent prices.

-

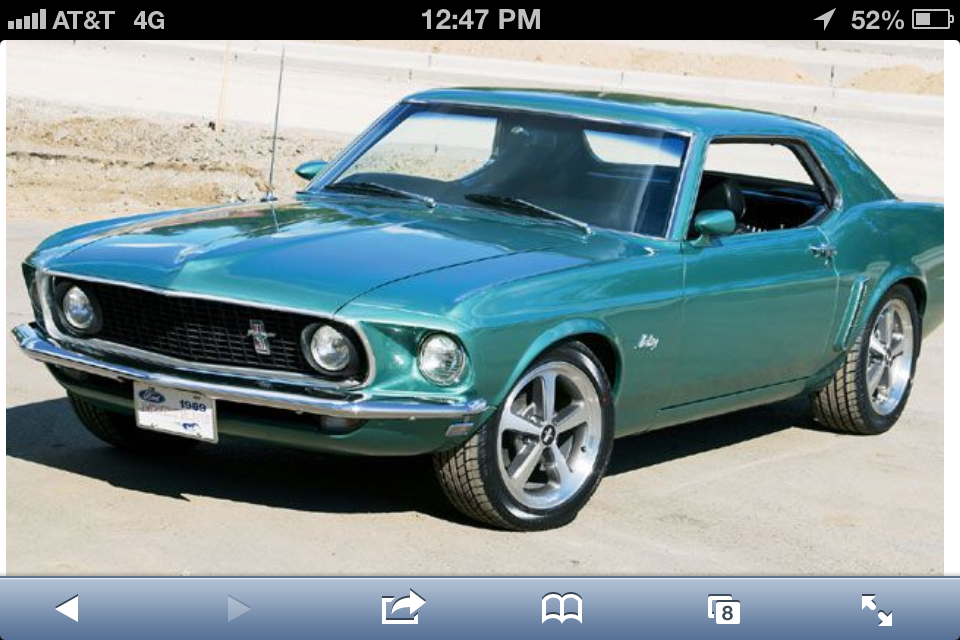

It's close to silver jade, just a little darker.

-

-

-

I'd prob jack it up to take the weight off, loosen, then let it back down then torque to spec. Before you torque to spec maybe roll the car backwards a few feet then fwd a few feet to let the front end settle. I put Global West LCA's on my car and they have spherical bearings instead of the rubber/bushing combo so with mine, tightening those bolts is ok with car on jackstands. If you have the eccentrics on there, make sure and take note of where they are prior to loosening/retightening. I used eccentric eliminators.

-

Just replaced my front end as well. If you used a stock style lca, did you remember to not torque down the frame mounts until the weight of the car was on them?

-

[ATTACH]13735[/ATTACH]

Not sure if they are available anymore but I really like my Formuling wheel. Bought it from California Mustang 10+ years ago. The center pad is removable so it's sorta like 2 steering wheels in 1. When the pad is off the spokes are silver and the horn is black.

-

I am going to put these on my 69 coupe. On the drivers side, it seems that the fuel line will need to be moved in order to safely weld there. The fuel line is right up next to the subframe in front. Has anybody had to do this and what is the easiest way to temporarily move it for the install. Any other tips? I already have the connectors and a pipe fitter/car guy friend that's going to weld em in, just want to have everything ready when he comes over to do the welding.

-

It's pretty tough to see the pic on my phone but as long as it's metal I'm sure it can be welded back together.

-

I ran 1.25" spacers front and rear on my 69 coupe with 03 Mach 1 rims. Bought all 4 spacers on eBay for 100.00.

-

Just replaced my UCA's on my 69 coupe. Lots of dirt/old grease and stuff was accumulated in this area. Cleaned it all out. Seemed to be some type of filler or built up undercoating was intentionally built up there on both sides. After removing all of it I noticed there were drain holes at the bottom that were obviously not functional with all that gunk built up in there. Should I refill the area with something or just treat the metal and let the drain holes function? I never intentionally drive my car in the rain/ mud btw.

-

Second time, I took a picture of the lug nut, emailed it to McGard, and then they helped me buy the tool that fit it. I didn't have a torch to use to replicate the first method and the wheel had very deep lug nut recesses so there weren't too many options that wouldn't ruin the wheel.I like that idea best! I'd hate accidentally messing up a good wheel.

Do you carry a spare?

in 1969-70 Technical Forum

Posted · Report reply

I run late model 17" rims. Got a 17" spare from the same car to go with them and it doesn't take up much room at all.