70fastbak

-

Content Count

491 -

Joined

-

Last visited

Posts posted by 70fastbak

-

-

Shifter plate, standard for 4 speed.

If anybody has one.

-

I see what you did.

It turned out pretty good but maybe I wasn't 100% clear on what I wanted or called it the wrong part.

The part I need is actually the part that has the shifter hole in it.

-

Nice work 70fastbak! I wish I had your talents.Thank you sir.

I wish I got payed enough for my talent, lol.

-

I would recommend bench bleeding your master cylinder before you install, it will make bleeding your brakes a lot easier.

-

I wasn't insulting you, I was just stating a term that is used at my place of work, more so my boss, he calls that the hillbilly way.

I don't personally call it anything, its just another way of doing it.

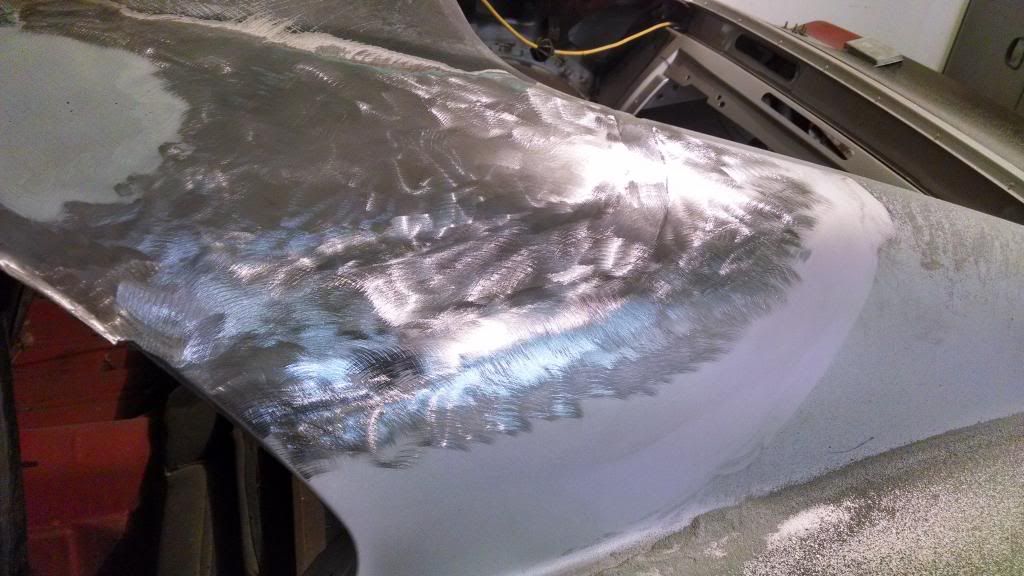

As for the welding statement you made, its all welded up, what your looking at is something we use instead of filler.

I personally prefer to do it the old fashioned way and lead it like I did on my own car.

-

-

-

Powerblock on SpikeTV actually did an episode where they converted a 67 coupe to a fastback, but the older Mustangs are different and nothing like the 69-70 structure.http://www.powernationtv.com/episode/DM2014-12/plain-pony-to-fastback

More pics would be great thanks. I'll keep in touch, right now I don't even have all the tools yet so I'm gonna go shopping this weekend first. Orchard Supply has a no sales tax event this Sat and Sun.

Ok just let me know.

-

That's beautiful, 70fastbak! Thanks so much for the pics! I'll definitely give your method a shot, any more pics and advice you can provide?Its the most time consuming way but like I said in my opinion the correct and only way to do it.

One thing I will add is that the filler panel and trap door surround can be taken out with the roof when its lifted off (forgot to mention that, sorry).

Once again, no cutting just breaking spot welds.

I will help you anyway I can, im sure I have more pics somewhere, if you want to talk pm me and I will give you my phone number.

-

Each person have their own different ways I guess.

We call that the hillbilly way and I would get fired if I did it that way but whatever works.

Its for sure the faster way but I need my job so I do it the way I wont get fired.

-

-

-

-

-

-

-

-

-

Here are a few pics I found of the last coupe to fastback I did.

Not sure they will help you too much but you can see how involved it is and maybe show you that there is no cutting involved whatsoever.

Its just drilling out spot welds, no cutting on the pillars or on the rear inner roof structure.

-

Ive actually done a few of these at work.

The only way to do it right in my opinion is to take the roof off right at the spot welds it was joined with.

Its a time consuming task, where the top door hinge is you will see a bunch of spot welds that you have to break loose, there will be some on the inside also, you can cut the cowl off at the ends to help you see and give better access also.

At the back of the car you will have to cut the quarters off and break loose all the spot welds that are on top of the wheel tubs to free the inner roof structure.

Not for the faint hearted but I think its the only way to do it correctly.

-

yeah, if you decide to use them just trim the leading edge and seam seal.I think I will use them and do what you said, I bought one of those seam sealer guns that can spray so I can do all kinds of finishes with it.

I will cut and spray seam sealer around it.

Thanks for all the replies guys.

-

So it looks like the forward edge of these plates goes under the floor from looking at your pictures, which sucks because I just welded my new floor in today, lol.

Maybe if 70 cars didn't use these plates I just wont bother after all.

-

I just purchased the console gauge pod from mustangs unlimited.

The texture isn't quite the same as the console texture.

Once installed with gauges and in the car im sure it wont be noticed.

-

Are all front brake lines the same on power cars.

Or is there a difference between power drums and power disc ?

I bought the masterpower front disc conversion kit for an original drum car.

Im wanting to buy some parts while cj's has their sale going on.

Tell me about "Wide Band Air Fuel Ratio"

in 1969-70 Technical Forum

Posted · Edited by 70fastbak · Report reply

I could go on and on about this topic.

Ive had/built a lot of turbo mustangs, mustang cobras.

I personally have always used AEM wideband gauges and had good luck with them.

They have also come down in price considerably since I bought my first one.

It tells you right on the AEM turbo forums and the install instructions to have the O2 sensor no more than 18" from the manifolds because it has to be kept within a certain temp.

A good place to weld the O2 bungs if you run two sensors is just on the bend a few inches before the collectors or even in the collectors.

Remember to angle the sensor at around a 10 degree downward angle so moisture does not collect in the sensor tip.

Just make sure to go with a good wideband, innovate LC1 is another good one, stay away from narrowband they are nothing more than flashing disco lights in your dash/pod that tell you nothing.

You should be fine using just one sensor but ive seen two in dual exhaust cars also.

Most of the turbo cars ive had I fabricated my own kits and they have ended up being a 4" single exhaust right from the turbo back into a muffler so ive never had a reason for two sensors.